How a private mobile network can help manufacturers in Australia overcome their biggest challenges.

Manufacturers in Australia and around the world are facing mounting pressure to boost profitability amid high inflation, rising interest rates, and escalating energy costs. To stay ahead, they must improve operational efficiency, optimise resources and meet increasingly demanding customer expectations, all while maintaining high product quality and tight delivery timelines.

The key to overcoming these challenges lies in harnessing the power of Industry 4.0 technologies. However, to truly unlock their potential, manufacturers need a connectivity solution that is fast, reliable, and secure. That’s where Private Mobile Networks (PMNs) come in. A Private Mobile Network (PMN) is a dedicated, standalone cellular network designed exclusively for an organisation’s use, providing secure, reliable, and high-performance connectivity tailored to specific operational needs. It offers ultra-low latency, high-speed data transfer, and interference-free communication, making it ideal for demanding environments like manufacturing. With full control over the network, organisations can prioritise critical applications, safeguard sensitive data, and ensure seamless integration with advanced technologies such as IoT, robotics, and AI—unlocking new levels of efficiency, innovation, and scalability.

Top PMN use cases in manufacturing

- Automated guided vehicles – Autonomously move objects from one part of your campus to another with a PMN’s seamless connectivity — both indoors and outdoors.

- Collaboration robots – Simplify the management of a fleet of cobots and other industrial equipment by centralizing configuration through a PMN capable of transporting industrial fieldbus communications protocols over wireless channels.

- Condition monitoring sensors – Detect small issues before they become bigger and costlier problems with PMN-connected sensors, lowering maintenance costs and reducing unplanned downtime.

- Augmented reality – Facilitate equipment maintenance and troubleshooting with wireless AR headsets that can display 3D overlays on real objects and enable remote OEM support.

- Video analytics – Promote worker health and safety, identify manufacturing defects, and improve product quality assurance using algorithms and smart vision — enabled by the real-time data transfer capabilities of a PMN.

Boosting productivity, streamlining operations

Industry 4.0 has brought applications that can serve manufacturers of every kind. A PMN is the optimal connectivity solution for many of these and can be deployed in any manufacturing environment: from vehicle assembly lines, food and beverage facilities, chemical plants, to paper mills and everything in between.

For example, consider automation. While automation isn’t new to manufacturing — companies have long used it to complete routine tasks faster and more consistently — however a greater number of manufacturing tasks have become ripe for automation as technology has evolved. Automated guided vehicles (AGVs), like self-driven forklifts, can move pallets and other heavy objects from one building to another, such as from a factory to a distribution centre or storage area on the same campus. In many manufacturing plants, this means having the AGV move between indoor and outdoor environments and rely on network connectivity to coordinate tasks and optimise routing. That’s where a PMN becomes essential.

AGVs need consistent and reliable network connectivity as they move between locations. A PMN is best suited to meeting this requirement because it can provide wireless coverage across a manufacturer’s entire campus, including all indoor and outdoor areas. At the same time, a PMN’s dedicated spectrum eliminates interference from other sources, such as in dense Wi-Fi networks, while seamless handoffs between radio cells ensure uninterrupted connectivity. Wi-Fi networks, on the other hand, struggle to keep AGVs connected as they travel across a facility, often dropping the connection when switching between access points. As for public mobile networks, they offer limited indoor coverage in manufacturing environments, which often include many metal obstructions and surfaces that can disrupt public mobile signals coming from outside. They also have a greater potential for unplanned downtime because availability and maintenance windows for public mobile sites are often unknown and beyond the manufacturer’s control.

Another technology that can benefit from PMN connectivity are collaboration robots (or cobots), which are designed for safe operation alongside human staff. These are more flexible than the heavy-duty industrial robots that have been used in production lines for quite some time. Manufacturers can configure an individual cobot to assist with a range of tasks, from assembly and machine tending to welding and packaging. In this way, cobots can help companies manage labour shortages and boost operational efficiency. While a single wired cobot is relatively easy to configure manually, when there’s a fleet of them, remote configuration is far more efficient. It means a human doesn’t have to walk up to each cobot and interact with a human–machine interface (HMI) panel to do the programming. Instead, the employee can configure and monitor the entire fleet from a centralised location through remote HMIs accessed on work machines and tablets.

A PMN enables this, while also providing coverage everywhere cobots might travel in a facility. This allows the cobots — and other smart manufacturing equipment, such as computer numerical control (CNC) machines — to go cable-free and become nomadic, improving mobility, reducing complexity, and creating more dynamic facilities that can quickly change their production layouts to adapt to new customer demands and product requirements.

The ability of a PMN to simplify asset management and configuration goes beyond cobots. In process control and automation systems, programmable logic controllers (PLC) perform the critical real-time function of using inputs from sensors to control actuators based on programmed routines. PLCs are typically connected to distributed field input/output devices using wired connections. There’s also often a need for communication between PLCs to synchronise operation across multiple automation systems working in tandem, such as in an assembly or packaging line. A 5G PMN can eliminate the need for complex cabling and network infrastructure to interconnect the high volume of devices and controllers distributed across a modern manufacturing facility. Collectively, this cabling and infrastructure often represent a major expense for any manufacturer. The ultra-reliable, low-latency capabilities of a 5G PMN make it possible to transport industrial fieldbus communications protocols over wireless channels.

Maintaining assets, enhancing safety

IoT solutions can help manufacturers extend the life of equipment and assets such as mixers, pumps and conveyor systems. Condition monitoring sensors installed in these machines can measure variables like vibration and temperature in real time. When these insights are combined with historical data on failure rates and their root causes, the solution can predict the likelihood of future failures based on current conditions. This way, manufacturers can detect problems and, through predictive maintenance, resolve them before they become bigger and costlier issues. This also helps prevent unplanned downtime that can disrupt production.

For any of this to work, sensors need reliable wireless connectivity to ensure they can collect and transmit data about a machine’s condition in real time. This applies to other IoT applications in manufacturing as well, such as the use of wearables to improve worker safety by detecting when someone enters a restricted area or is in proximity of oncoming vehicles and heavy machinery. A PMN can provide the continuous connectivity IoT sensors need.

Augmented reality (AR) is another technology with significant applications for manufacturing, including asset maintenance. Employees wearing AR headsets can see a 3D overlay of equipment with labels and instructions for completing routine maintenance tasks. For instance, the overlay can indicate which panel to open and buttons to press. If the user encounters an issue they’re unfamiliar with, they can share what they’re seeing with a technician from the original equipment manufacturer (OEM), who can help them address it remotely. That means there’s no need for the OEM to travel to the factory to resolve the issue in person, minimising potential downtime.

Video analytics solutions also have applications in manufacturing. For instance, they can help assess how an employee is lifting a heavy object and flag if they’re doing so in a way that could be harmful. The employee can then be trained on the proper form or technique to promote better long-term health. Smart vision can also be used to identify manufacturing defects and improve product quality assurance. These kinds of solutions rely on algorithms to analyse and make determinations about the footage that is being captured. The fast speeds of a PMN are what enable the real-time data transfer between cameras and the data centre where the processing happens.

PMNs in action

None of these applications are theoretical. A PMN can enable them all — today. Many manufacturers have already done so, including the world’s largest chemical company, BASF, and the Australian Meat Processor Corporation (AMPC).

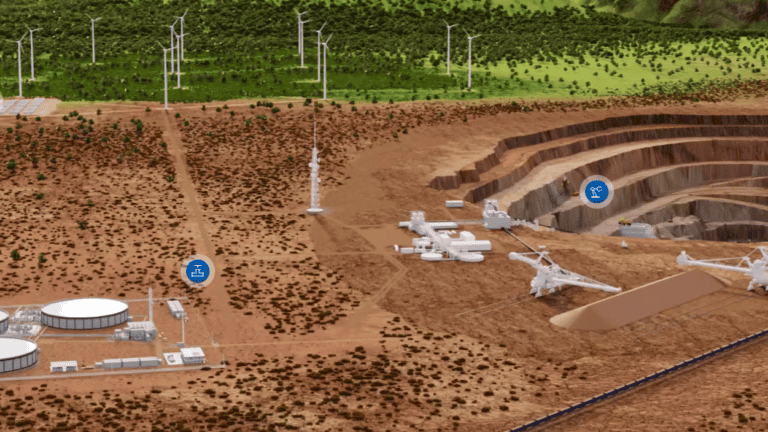

BASF

BASF wanted to adopt IoT, AR and artificial intelligence (AI) solutions to enhance its operations, security and other key areas, but came up against the limitations of public mobile connectivity. For example, public networks are unable to support large numbers of connected devices across more than 100 hectares and to meet strict data security requirements. In partnership with BAI’s sister company, Boldyn Networks, BASF deployed the first-ever 5G PMN for the chemical industry in Spain. Now the company has fast and reliable wireless connectivity across its facilities, with scalable capacity to support increasing numbers of connected assets and workers. The connectivity has helped BASF improve worker safety by supporting precise, real-time tracking of employees and providing low latency for the safe operation of automated vehicles. BASF is also using AR to accelerate repairs, with crews able to photograph and scan issues and see instructions on how to address them.

AMPC

To help AMPC drive productivity and efficiency in a highly regulated industry, BAI designed, supplied and installed a 5G PMN for a regional processing facility. The fast, powerful and dedicated wireless connectivity of the 5G PMN allowed the company to trial smart technologies for remote auditing and compliance monitoring, such as live video streaming augmented by computer vision technology. The trial proved the viability of these solutions and their potential benefits in conjunction with a PMN, including helping AMPC realise significant time and cost savings. For example, with the 5G PMN in place, veterinarians can assess animals at the facilities remotely, from any location. The company also has access to smart solutions that can accelerate operations and minimise errors, such as an AI-driven platform able to verify that cartons contain the specified product.

Enhance your manufacturing operations with BAI

A PMN will be key to solving many of the challenges facing manufacturing companies in Australia. Those that continue to rely on just Wi-Fi or public mobile networks for connectivity risk falling behind as competitors advance their digital transformation journeys and deepen their investments in Industry 4.0 technologies — while preparing for the next leap into 5.0. The future of manufacturing will see AI working in concert with humans to achieve unprecedented levels of productivity, efficiency, safety, and innovation.

BAI is equipped to empower manufacturers on this journey with custom-built 4G/5G PMNs. As part of this commitment, BAI has secured licensed spectrum in the 3.8 GHz band from the Australian Communications and Media Authority (ACMA). This strategic acquisition, which strengthens BAI’s existing spectrum holdings, will support the deployment of dedicated, high-speed networks across key metropolitan and regional areas. With this new spectrum allocation, manufacturers will benefit from low-latency, interference-free connectivity that’s crucial for automation, IoT deployment, and real-time data processing.

Drawing on our extensive experience in delivering advanced communications infrastructure, BAI is ready to support manufacturers as they transition to Industry 4.0 and prepare for future advancements. By providing dedicated, scalable, and secure connectivity solutions, BAI will enable manufacturers to stay ahead of the competition, optimise operations, and unlock the full benefits of digital transformation.

Contact us to learn how our team can help you put in a place a private mobile network tailored to your operations or download our brochure for more information on our connectivity solutions.